I’ve been pushing a couple of audio amp chips to get as much out of them as I can for another project. While the expected duty cycle is low enough that I can probably get away without heat sinks for the final application, the parts get pretty hot when they’re run long enough to do testing and make measurements. It seemed like a good idea to put at least some minimal heat sinks on them.

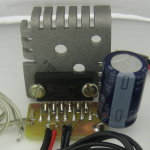

The larger of the amp chips, a TDA1518, got so hot so fast that I’d already hacked a quick heat sink on to it. I’d laid the board out so the back thermal surface of the Multiwatt package was flush with the edge of the board, so it was easy to bolt an old TO-3 heat sink to it (with some thermal grease, of course).

The larger of the amp chips, a TDA1518, got so hot so fast that I’d already hacked a quick heat sink on to it. I’d laid the board out so the back thermal surface of the Multiwatt package was flush with the edge of the board, so it was easy to bolt an old TO-3 heat sink to it (with some thermal grease, of course).

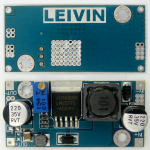

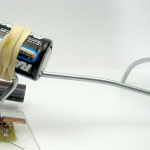

But that was only part of the problem: I was using a DC boost converter to get ~15V from a 3.6V Li-ion battery, and that converter was getting hot, too. Fortunately, there were a whole bunch of vias to provide thermal connection from the chip to the back of the board. I found a strange tower-like

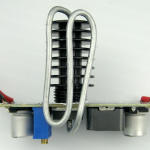

But that was only part of the problem: I was using a DC boost converter to get ~15V from a 3.6V Li-ion battery, and that converter was getting hot, too. Fortunately, there were a whole bunch of vias to provide thermal connection from the chip to the back of the board. I found a strange tower-like  cylindrical sink in the junk box whose transfer surface just about matched the one on the back of the converter board. But how to hold it on? That nice #7 soft steel wire doesn’t have a lot of spring, but there was just enough for this snake to clamp the sink down nicely, if temporarily. Some more thermal grease, and I’m sure the chip was very happy to be able to snuggle up to that nice cool aluminum tower!

cylindrical sink in the junk box whose transfer surface just about matched the one on the back of the converter board. But how to hold it on? That nice #7 soft steel wire doesn’t have a lot of spring, but there was just enough for this snake to clamp the sink down nicely, if temporarily. Some more thermal grease, and I’m sure the chip was very happy to be able to snuggle up to that nice cool aluminum tower!

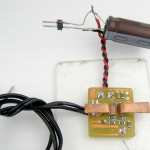

The other amp, a little MAX98307, didn’t handle nearly as much power as the first one, but still got pretty hot. It had a thermal pad on the bottom, but with my single-sided boards, that wasn’t very useful. With its tiny top surface, there wasn’t much to make thermal contact with, and other components on the board were taller than the chip, so I

The other amp, a little MAX98307, didn’t handle nearly as much power as the first one, but still got pretty hot. It had a thermal pad on the bottom, but with my single-sided boards, that wasn’t very useful. With its tiny top surface, there wasn’t much to make thermal contact with, and other components on the board were taller than the chip, so I  couldn’t even clamp a large flat sink to it.

couldn’t even clamp a large flat sink to it.

I cut and bent up a bit of scrap copper sheet to about the right width, but any movement was likely to short out other components, so a kluge clamp like the one above wasn’t a great plan.  I didn’t have any thermally conductive glue, so I used normal 5 minute epoxy and made a single point of contact vertical gravity clamp to squish it out as thin as I could, in hopes that that thin layer wouldn’t present too much thermal resistance. (I go through a lot of that nice #7 wire.) A bit of scrap plastic for a base gave the sink a little protection from being cracked off.

I didn’t have any thermally conductive glue, so I used normal 5 minute epoxy and made a single point of contact vertical gravity clamp to squish it out as thin as I could, in hopes that that thin layer wouldn’t present too much thermal resistance. (I go through a lot of that nice #7 wire.) A bit of scrap plastic for a base gave the sink a little protection from being cracked off.

As with the bigger amp and converter above, I don’t have any easy way to measure how much cooler it runs, but I have to believe it’s a lot better off than it would be with nothing. And all 3 components survived at just below clipping for long enough to make the observations and measurements I needed, so I guess the sinks did their jobs.

Adafruit recently came out with a few small audio amplifiers <$10.

http://www.adafruit.com/products/1552

http://www.adafruit.com/products/987

http://www.adafruit.com/products/1712

Thanks, Jim. The one in the middle link is the stereo version of the smaller chip I used.

Either of the first 2, plus one of her little speakers and a small LiPo in a small-as-possible case would be perfect for a small general purpose bench audio amp. With my testing done, I’ll probably use the little one above to make a nicer replacement for the LM386 based one built in a transistor radio case that’s been banging around on my bench for – um – a lotta years.

I got one of those too, a radio shack amp/speaker about 4″ square. Had it for 20 years.