I’ve worried for years that at least some of the NiCd chargers’ trickle charge regimen was cooking my batteries into oblivion. They say you can charge sub-C NiCds at 100mA forever without problem, but for stuff that’s charging for months at a time (like lawn care tools over the winter) I’d like considerably less.

After I rebuilt one of the 18V sub-C batteries for my B&D “Cordless Broom” blower, I wanted to treat it well. Leaving it on the factory charger resulted in it being quite warm after while, and a check (with a 0.1Ω resistor in series) showed it was still pumping a little over 200mA through the battery. I need a current limiter!

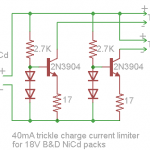

I found a fairly simple limiter circuit that seemed appropriate. When the current thru the emitter resistor causes a voltage drop around 0.7V, the transistor starts to shut off. Using that design, I started out to make something to use my one charger to trickle charge my two batteries more appropriately.

The first order of business was making contacts to plug into the charger and battery. To connect to the charger, I simulated the battery contacts with a couple of pieces cut from an old PC expansion slot cover epoxied to a scrap of wood. Using an oversized piece of wood ensured that it could only be plugged in one way. (The geometry of the charger is such that the red + marking is correct despite the apparent mismatch with the red + blade of the battery.)

The first order of business was making contacts to plug into the charger and battery. To connect to the charger, I simulated the battery contacts with a couple of pieces cut from an old PC expansion slot cover epoxied to a scrap of wood. Using an oversized piece of wood ensured that it could only be plugged in one way. (The geometry of the charger is such that the red + marking is correct despite the apparent mismatch with the red + blade of the battery.)

To connect to the battery, I fashioned some springy clips out of brass strip and epoxied those to another scrap of wood. Again I located the contacts on the wood so it could only plug into the battery one way. I added some heat shrink and tape to make it a little more proper.

To connect to the battery, I fashioned some springy clips out of brass strip and epoxied those to another scrap of wood. Again I located the contacts on the wood so it could only plug into the battery one way. I added some heat shrink and tape to make it a little more proper.

I built the 2 channel current limiter on a bit of perfboard and glued it to the fake connector that plugs into the charger. (I used 2N2222s.) I also put a 0.1Ω resistor in series with the whole thing so I could measure current if I needed to.

I built the 2 channel current limiter on a bit of perfboard and glued it to the fake connector that plugs into the charger. (I used 2N2222s.) I also put a 0.1Ω resistor in series with the whole thing so I could measure current if I needed to.

Since the male input connector and the female output connectors matched, I thought I’d see if I could make it self-powered by plugging the output into the input. (I could still use the second channel to trickle charge one battery.) Unfortunately, the current limiter just got real hot and burned out the transistor on the side whose output I was using, so it didn’t work. I guess perpetual motion really doesn’t work 🙂

Since the male input connector and the female output connectors matched, I thought I’d see if I could make it self-powered by plugging the output into the input. (I could still use the second channel to trickle charge one battery.) Unfortunately, the current limiter just got real hot and burned out the transistor on the side whose output I was using, so it didn’t work. I guess perpetual motion really doesn’t work 🙂

It’s still a little bit of a hassle to use. For a normal recharge, I slide the charger on the battery just like the manufacturer designed. The charger is rated at 210mA, so after maybe 6 or 8 hours bulk charging is complete, so I take the charger off and plug the trickle current limiter into the charger and the battery. But now I’m comfortable leaving it that way all winter!

It’s still a little bit of a hassle to use. For a normal recharge, I slide the charger on the battery just like the manufacturer designed. The charger is rated at 210mA, so after maybe 6 or 8 hours bulk charging is complete, so I take the charger off and plug the trickle current limiter into the charger and the battery. But now I’m comfortable leaving it that way all winter!

I did run the blower with the rebuilt battery after it had been on the trickle charger for a couple of days. It worked great. And when I get around to rebuilding the second battery, I’ll also make another battery-end adapter for it. The charger should be able to handle two 40mA trickles at the same time.

Maybe the next limiter will be for that dustbuster that lives under the sink, is always warm when I pick it up, and whose battery never seems to last very long.