Faced with a potentially large number of welds for rebuilding a DeWalt battery, I finally integrated two improvements that have been waiting in the wings: a MOSFET charger disconnect and a foot pedal to disconnect the charger and fire the SCR (in that order).

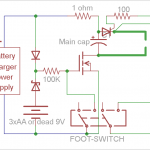

Here’s the new schematic. The MOSFET cuts off power from the charger momentarily during discharge so it doesn’t keep the SCR turned on. Since the gate needs a few volts to keep it turned on, powering it from the top of the cap doesn’t work for the end of the discharge cycle – thus the battery. I was originally going to put 3 AAs in, but realized a 9V battery past the end of its useful life would be perfect. And I have a lot of those lying around.

Here’s the new schematic. The MOSFET cuts off power from the charger momentarily during discharge so it doesn’t keep the SCR turned on. Since the gate needs a few volts to keep it turned on, powering it from the top of the cap doesn’t work for the end of the discharge cycle – thus the battery. I was originally going to put 3 AAs in, but realized a 9V battery past the end of its useful life would be perfect. And I have a lot of those lying around.

I built up the MOSFET on a bit of perfboard and found a nice mount for it on a thermal cutoff or something in the charger housing that passed the low side lead. A four position terminal strip provides connections to the foot pedal switches.

I built up the MOSFET on a bit of perfboard and found a nice mount for it on a thermal cutoff or something in the charger housing that passed the low side lead. A four position terminal strip provides connections to the foot pedal switches.

Since I was in a hurry <sigh> I wired it all up, but didn’t do final mounting. The wires for the foot pedal just come out of vents in the case, and it’s all just kind of hanging in the breeze. But it was sufficient for the job at hand. And it all worked together perfectly.

Since I was in a hurry <sigh> I wired it all up, but didn’t do final mounting. The wires for the foot pedal just come out of vents in the case, and it’s all just kind of hanging in the breeze. But it was sufficient for the job at hand. And it all worked together perfectly.

Since the power supply can generate DC voltage greater than the cap’s absolute max, I had to cheat to protect the cap. After each weld, I’d remove the electrodes and then quickly hit the foot switch again, cutting power to the cap while I lined up the next tab. I’d position one electrode, but since the foot switch being down left the electrodes potentially hot (oops) I’d take my foot off the switch before I positioned the other electrode. Then I’d watch the voltage climb to the desired ~15.5V and hit the foot switch again to make the weld. The undesirable noise and sparks kept me from blowing that sequence of events more than about once.

So the next, and final (well, maybe except for a handle) improvement (OK, and mounting those last parts more permanently) is a voltage/power control. The “wire or” MOSFET control design should allow for this nicely: Any other closure to ground will also disconnect power from the cap. All I should need is a comparator on the cap voltage with its other side on a pot, all turning on a relay or transistor when the voltage meets the setting. A voltmeter would be nice, too. And maybe when I make that I’ll mount all the parts neatly as well.

Pingback: DeWalt battery rebuild | Jim's Projects