I’ve used my 18V B&D cordless blower to clean grass clippings off the sidewalk after mowing for many years. It’s great. The 15 cell sub-C NiCd battery packs didn’t last for a whole cleanup – but I had two, rebuilt them, and limped along. Then I hacked the nice 3.3 A-hr Li-ion pack in and it would run 2 or 3 cleanups between recharges. Great! (OK, and ugly. But it works.)

I’ve used my 18V B&D cordless blower to clean grass clippings off the sidewalk after mowing for many years. It’s great. The 15 cell sub-C NiCd battery packs didn’t last for a whole cleanup – but I had two, rebuilt them, and limped along. Then I hacked the nice 3.3 A-hr Li-ion pack in and it would run 2 or 3 cleanups between recharges. Great! (OK, and ugly. But it works.)

Today it sputtered and died most of the way through the cleanup. Grumble, get the  broom, grumble… After sweeping up, I checked and there was in fact voltage at the connector into the blower. (While the original plan was to fit the Li-ion into one of the old battery pack shells (though sticking out one end), all I ended up keeping was the connector from the old pack. It’s connected to banana plugs that mate with the battery with a piece of 18-2 zip cord. That wire’s not really big enough – it gets warm when the blower runs for more than a minute or so.)

broom, grumble… After sweeping up, I checked and there was in fact voltage at the connector into the blower. (While the original plan was to fit the Li-ion into one of the old battery pack shells (though sticking out one end), all I ended up keeping was the connector from the old pack. It’s connected to banana plugs that mate with the battery with a piece of 18-2 zip cord. That wire’s not really big enough – it gets warm when the blower runs for more than a minute or so.)

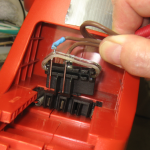

Great – did running a motor designed for 18V NiCds on a hot 18.5V Li-ion burn out the brushes? It’s noticeably louder (and higher pitched and more effective!) with the new battery. So I took it apart, and the problem was immediately clear: One of the motor wires was disconnected.

Great – did running a motor designed for 18V NiCds on a hot 18.5V Li-ion burn out the brushes? It’s noticeably louder (and higher pitched and more effective!) with the new battery. So I took it apart, and the problem was immediately clear: One of the motor wires was disconnected.

Worse: The terminal going into the motor was broken off below the surface. There’s really no way to fix that from the outside, and with the stamped/crimped construction of the motor, there was no simple way to take it apart. Rats.

Worse: The terminal going into the motor was broken off below the surface. There’s really no way to fix that from the outside, and with the stamped/crimped construction of the motor, there was no simple way to take it apart. Rats.

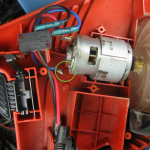

So the whole blower is now worthless. The chances of finding a replacement motor for less than a large fraction of the cost of a new blower are about nil.  With nothing to lose, I started trying to tear it apart in a way that might let me put it back together in case I figured out a way to actually fix that terminal.

With nothing to lose, I started trying to tear it apart in a way that might let me put it back together in case I figured out a way to actually fix that terminal.

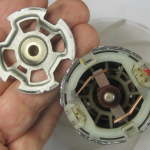

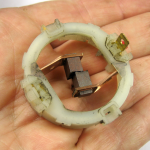

The end of the motor shell is crimped around the end plate. It’s steel and bent away only grudgingly to some end nippers. But bend it did, and the end plate (and bushing) came right out.

The end of the motor shell is crimped around the end plate. It’s steel and bent away only grudgingly to some end nippers. But bend it did, and the end plate (and bushing) came right out.

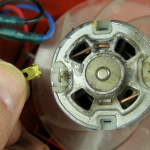

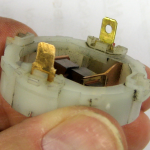

The remaining terminal is attached to a plastic brush holder ring.

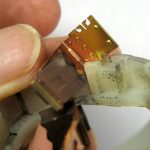

The remaining terminal is attached to a plastic brush holder ring.  That pulled right out, too. The brass terminal piece is riveted to the brush spring, and fits through a slot in the plastic ring. There was so little surface area where the terminal was broken off that there was no hope of

That pulled right out, too. The brass terminal piece is riveted to the brush spring, and fits through a slot in the plastic ring. There was so little surface area where the terminal was broken off that there was no hope of  reattaching it short of brazing, which I wasn’t comfortable with and might have hurt the brush spring.

reattaching it short of brazing, which I wasn’t comfortable with and might have hurt the brush spring.

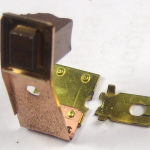

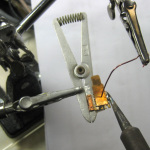

I decided to make an oversize new terminal out of some bronze? spring brass? strip I had and soft solder it to the remaining brass piece. The strip was 0.015″ thick and the original terminal was  0.020″, but I guessed it would work if I smushed the female terminal a little. Whether it ever gets hot enough to melt the solder is a good question. I tinned both surfaces first, made a jig to hold them together and sweated them. An aluminum clamp heat sink was there to try to protect the brush spring.

0.020″, but I guessed it would work if I smushed the female terminal a little. Whether it ever gets hot enough to melt the solder is a good question. I tinned both surfaces first, made a jig to hold them together and sweated them. An aluminum clamp heat sink was there to try to protect the brush spring.

It was obviously thicker overall than the original, but to my surprise took only a little forcing to fit into the original slot. Looks promising!

It was obviously thicker overall than the original, but to my surprise took only a little forcing to fit into the original slot. Looks promising!

When I went to crush the female terminal to fit the thinner male, I was quite surprised to find solder blobs on both females. I have no idea what that’s about.

When I went to crush the female terminal to fit the thinner male, I was quite surprised to find solder blobs on both females. I have no idea what that’s about.

Almost there! Now if I can just get it back together. Well, not quite. While I was pleasantly surprised at how much brush material remained, the commutator was kind of burned. The brushes were interestingly shaped so each touched the commutator at 3 places (hence the 3 burn rings). No good pic,  but you can see the cross section of the out-of-focus brush in the foreground in the picture above of how the terminal fits in a slot in the plastic ring.

but you can see the cross section of the out-of-focus brush in the foreground in the picture above of how the terminal fits in a slot in the plastic ring.

Anyway, a little emery cloth made the commutator at least look  prettier. The brush holder and brushes slipped right in, along with the metal end plate. Some creative placement on the anvil let me peen the crimped edges back over the end plate. It came out pretty well.

prettier. The brush holder and brushes slipped right in, along with the metal end plate. Some creative placement on the anvil let me peen the crimped edges back over the end plate. It came out pretty well.

I put it all back together, and it worked fine for a couple of minutes of cleaning up what the broom had missed on the grass clippings remaining after the blower failed. We’ll see how it holds up over time, but I’m pretty hopeful that I’ll get a few more years out of it.