I needed a better device to hold boards while in the CuCl2 bubble etcher. The plastic shipping holders from the coffee packet system (Flavia) we use at work looked like they might be useful someday, so over the past year I’ve collected a lot of them from the recycle bin. They’re 13.25″ long, pretty flexible, 30 mil thick, and can be bent with the flame of a match. I pressed some into use for the holder. I’ll make some more for other size boards, but I needed something good right now for the production run of latch boards for the scrolling LED display.

I needed a better device to hold boards while in the CuCl2 bubble etcher. The plastic shipping holders from the coffee packet system (Flavia) we use at work looked like they might be useful someday, so over the past year I’ve collected a lot of them from the recycle bin. They’re 13.25″ long, pretty flexible, 30 mil thick, and can be bent with the flame of a match. I pressed some into use for the holder. I’ll make some more for other size boards, but I needed something good right now for the production run of latch boards for the scrolling LED display.

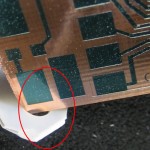

In addition to holding the board securely enough for the task, a big concern is that the holder can’t interfere with etching where it holds the board. Using the spring of the plastic and some minimal holes in the corners, I made a holder designed for these boards. The possibility of a “shadow” where bubbles can’t wash the surface with fresh etchant (red) was minimized by cutting the holder back as much as I was comfortable with.

In addition to holding the board securely enough for the task, a big concern is that the holder can’t interfere with etching where it holds the board. Using the spring of the plastic and some minimal holes in the corners, I made a holder designed for these boards. The possibility of a “shadow” where bubbles can’t wash the surface with fresh etchant (red) was minimized by cutting the holder back as much as I was comfortable with.

The board clips satisfyingly into the holder. Another strip of the same material epoxied to the back to hold the board upright provides a holder/hanger. Time will tell whether the plastic and epoxy will hold up to the acid etch bath.

The board clips satisfyingly into the holder. Another strip of the same material epoxied to the back to hold the board upright provides a holder/hanger. Time will tell whether the plastic and epoxy will hold up to the acid etch bath.

Seems to be working OK. Especially facing the production run of latch boards, it’s a delight to be able to set up and start an etch, set a timer, and forget about it. I’ve done two “reloads” and the plastic and epoxy seem to still be intact, though the epoxy is a little stained. The first board was completely etched when I checked on it after 20 minutes. The second took more like 40! After 20 minutes the top of the board seemed to be etched clean but not the bottom. I kept giving it another 5 minutes, but finally flipped the board over. The confidence that the etchant isn’t too nasty to skin gained in a demo at W88 allowed me to flip the board with my bare hands. (I did wash them right after that.) Another 5 minutes and it was done. I infer the bubble pattern isn’t as uniform as it should be. I flipped the 3rd board at ~25 minutes. Top was done. Looks like I need to do a flip at 10 or 12 minutes. Boards all came out fine.

Etchant is very obviously “dirty” – brown with CuCl. After 3 boards, it looks like between 4 and 10 g/l CuCl from Seychell’s color chart. I’ll try to pay attention to how long aeration takes to clear it back up.

Interestingly, splatters on the white plastic base of the etch tank (dripped while removing/reloading boards) over time self-aerate, getting visibly closer to the clear green of etchant containing little/no CuCl. (Very conveniently, droplets on the base work well to simulate Seychell’s “drop on a white card” test.) This picture, taken a few hours after the etching was done, show mostly “good” green, with the one dirty green in the upper right the result of an earlier CuCl color test. I’m sure that droplet was much darker when I made the test.

Interestingly, splatters on the white plastic base of the etch tank (dripped while removing/reloading boards) over time self-aerate, getting visibly closer to the clear green of etchant containing little/no CuCl. (Very conveniently, droplets on the base work well to simulate Seychell’s “drop on a white card” test.) This picture, taken a few hours after the etching was done, show mostly “good” green, with the one dirty green in the upper right the result of an earlier CuCl color test. I’m sure that droplet was much darker when I made the test.

An additional observation is that there’s significant corrosion of at least ferrous metals in the vicinity of where the aeration takes place. There was obvious rust on the side of a grinder near the etch bath, but none on the far side. The near side was maybe a foot away from the etch container. There was rust on other motor shafts and housings in the (crowded) area. I don’t know if it was from early bubbling in an open container or the current setup. In any event, it’s very obviously necessary to keep at least some kind of cover on the etch container, at least when the bubbler is on. I just used a small plastic bag formed a little to make a drip point for the etching today, and put it back when I started aeration. (To be clear: I turned the air pump on when I started etching and never turned it off. Of course some aeration was happening as a positive side effect while while the bubbles were doing mechanical agitation duty during etching . “… when I started aeration” was when I pulled the last board out and stopped etching.)

An additional observation is that there’s significant corrosion of at least ferrous metals in the vicinity of where the aeration takes place. There was obvious rust on the side of a grinder near the etch bath, but none on the far side. The near side was maybe a foot away from the etch container. There was rust on other motor shafts and housings in the (crowded) area. I don’t know if it was from early bubbling in an open container or the current setup. In any event, it’s very obviously necessary to keep at least some kind of cover on the etch container, at least when the bubbler is on. I just used a small plastic bag formed a little to make a drip point for the etching today, and put it back when I started aeration. (To be clear: I turned the air pump on when I started etching and never turned it off. Of course some aeration was happening as a positive side effect while while the bubbles were doing mechanical agitation duty during etching . “… when I started aeration” was when I pulled the last board out and stopped etching.)

Update 11/30/11: It’s finally time for a new holder. I’ve bent the original several times to fit various boards, and it’s still in one piece, but the first RF gun board is too big for it. And I wanted to get away from the epoxy holding the board clamp and the support piece.

Update 11/30/11: It’s finally time for a new holder. I’ve bent the original several times to fit various boards, and it’s still in one piece, but the first RF gun board is too big for it. And I wanted to get away from the epoxy holding the board clamp and the support piece.

Construction is essentially the same (the old one worked!), but now the parts are held together with a couple of 6-32 nylon machine screws. Should be fine.

Update 12/3/11: Here’s the smallest board I’ve needed to etch. It’s 3 instances of a breakout/mount for a Luxeon Rebel LED. This is the original holder – re-bent several times and still working fine. The epoxy is stained greenish, but still holds. (The nylon screws in the holder above also came out yellow-green after one etch.) This bend covers the corners more than the very first (and more than I’d prefer), but there’s a pretty big margin on this board and I don’t think it will be a problem.

Update 12/3/11: Here’s the smallest board I’ve needed to etch. It’s 3 instances of a breakout/mount for a Luxeon Rebel LED. This is the original holder – re-bent several times and still working fine. The epoxy is stained greenish, but still holds. (The nylon screws in the holder above also came out yellow-green after one etch.) This bend covers the corners more than the very first (and more than I’d prefer), but there’s a pretty big margin on this board and I don’t think it will be a problem.

I’m delighted with this material and approach. First, it really works. The plastic is just springy enough that it’s easy to insert/remove the boards, yet the holder is still very appropriately secure. And it’s free – all scrap. Can’t ask for much more!